TRIM premium

Vertical cutting machine

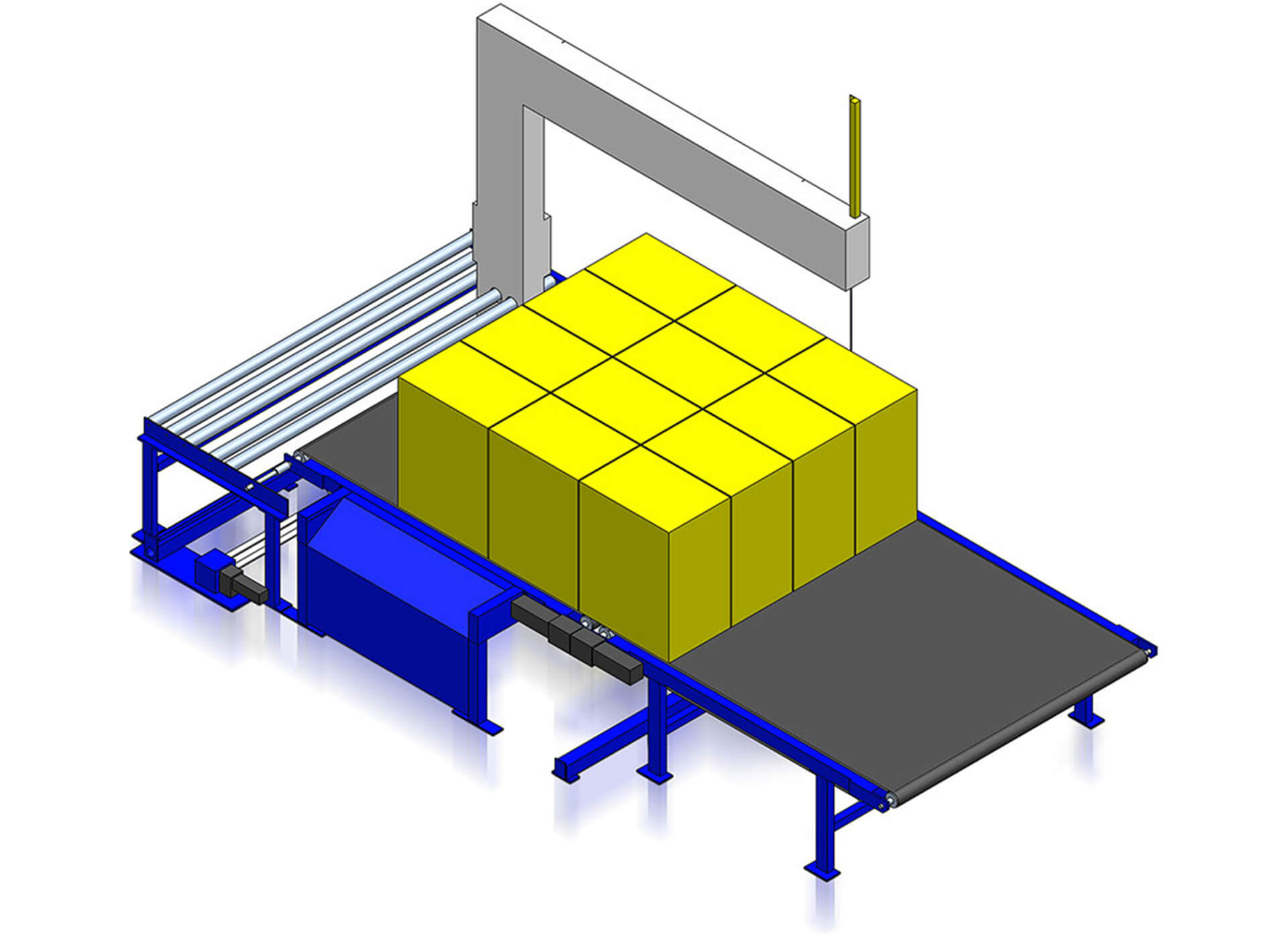

Cutting to length, trimming and dividing of blocks, space-saving and fast model (60m/min), fully automatic in new design

TRIM premium - Vertical cutting machine

Trimming blocks at high speed The TRIM premium is fully automatic and requires very little space - maximum speed 60 m/min. The state-of-the-art vertical cutting machine has been specially developed for cutting to length, trimming, trimming and dividing foam blocks. The new HMI of our SPS machines offers unique features and benefits that make them an indispensable tool in foam processing.

Technical data

The TRIM Premium is fully automatic and requires very little space - maximum speed 60 m/min. The state-of-the-art vertical cutting machine has been specially developed for cutting to length, trimming and dividing foam blocks.

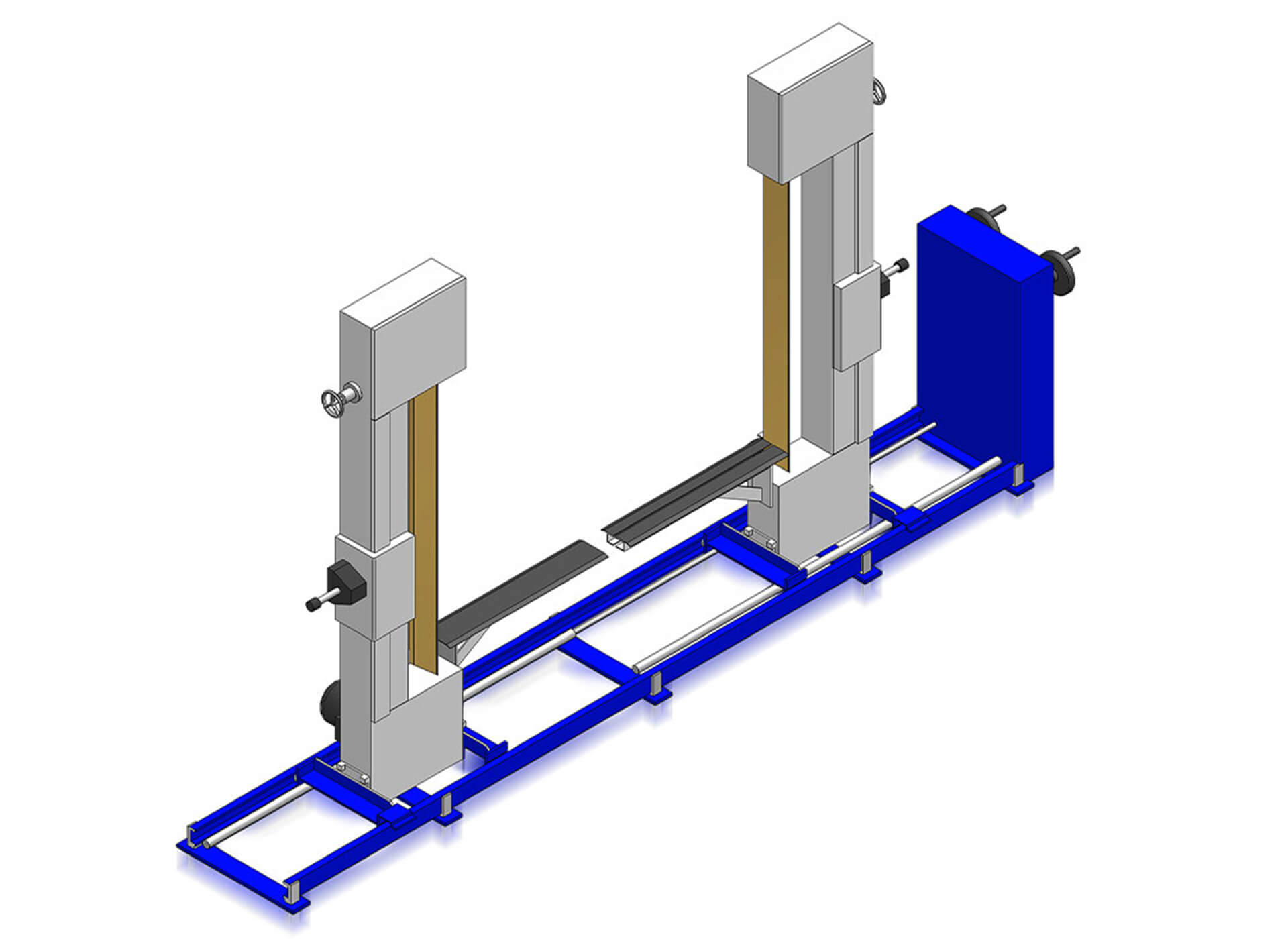

Dimensions

Standard Options Width 2200 mm 2500 mm Height 1500 mm 700 mm Length 2400 mm 2600 mm, 3050 mm, 4400 mm Material

Block and sheet ware made from PUR Soft Foam, PUR Rebond Foam, Visco-Elastic Foam, Latex

Cutting tools

GBV4T, TB2 No.28, TB2 No.29, TB2T-K18, TB1 No.14, TB1 No. 30

Cutting speed

max. 60m/min

Standard

Individually adjustable working modes

Transport conveyor system

with loading and unloading conveyors of various lengths for the processing of short blocks in automatic mode. The conveyorss are positioned either in front of or behind the machine. This serves to prevent machine downtime.

Options

Grinding dust extraction

for extracting the grinding dust during the grinding process.

Motor-driven grinding unit

Optional equipment of the machine with ground knife in connection with a motor-driven grinding unit.

Motor-driven knife guide (Basic)

to protect the knife in the unused cutting area. It reduces the non-guided knife length for better fixation of the knife, optimizes the cutting quality and enables the maximum cutting speed.

Cooling unit

In order to guarantee a safe operation of the machine, the entire interior of the switch cabinet is cooled.

Alignment station

For the precise positioning of the block. Recommended for the automatic feeding of the machine.