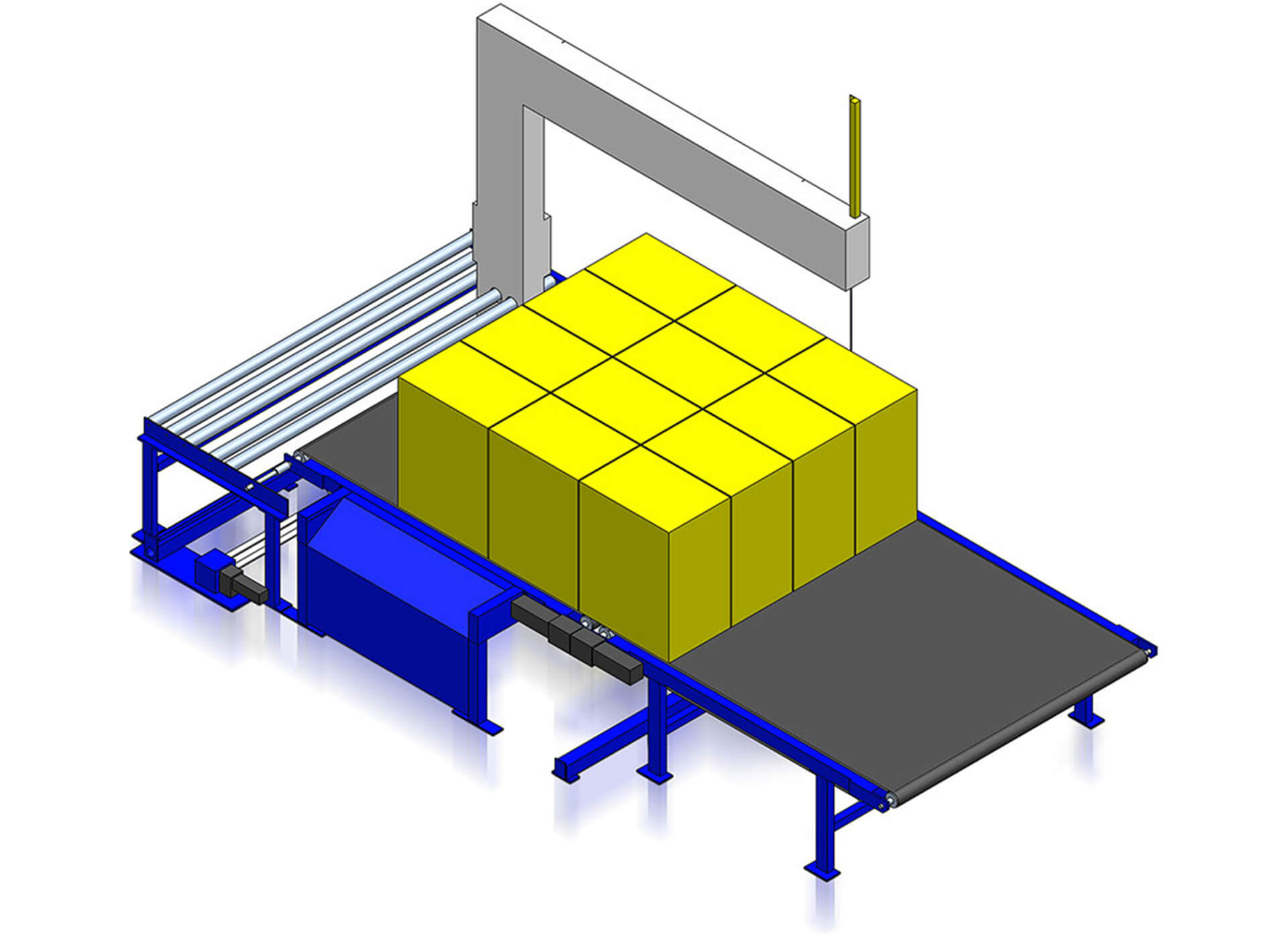

IS-M

Vertical cutting machine

Automatic trimming of blocks and cutting of sheets

IS-M: Vertical knife cutting has never been smarter

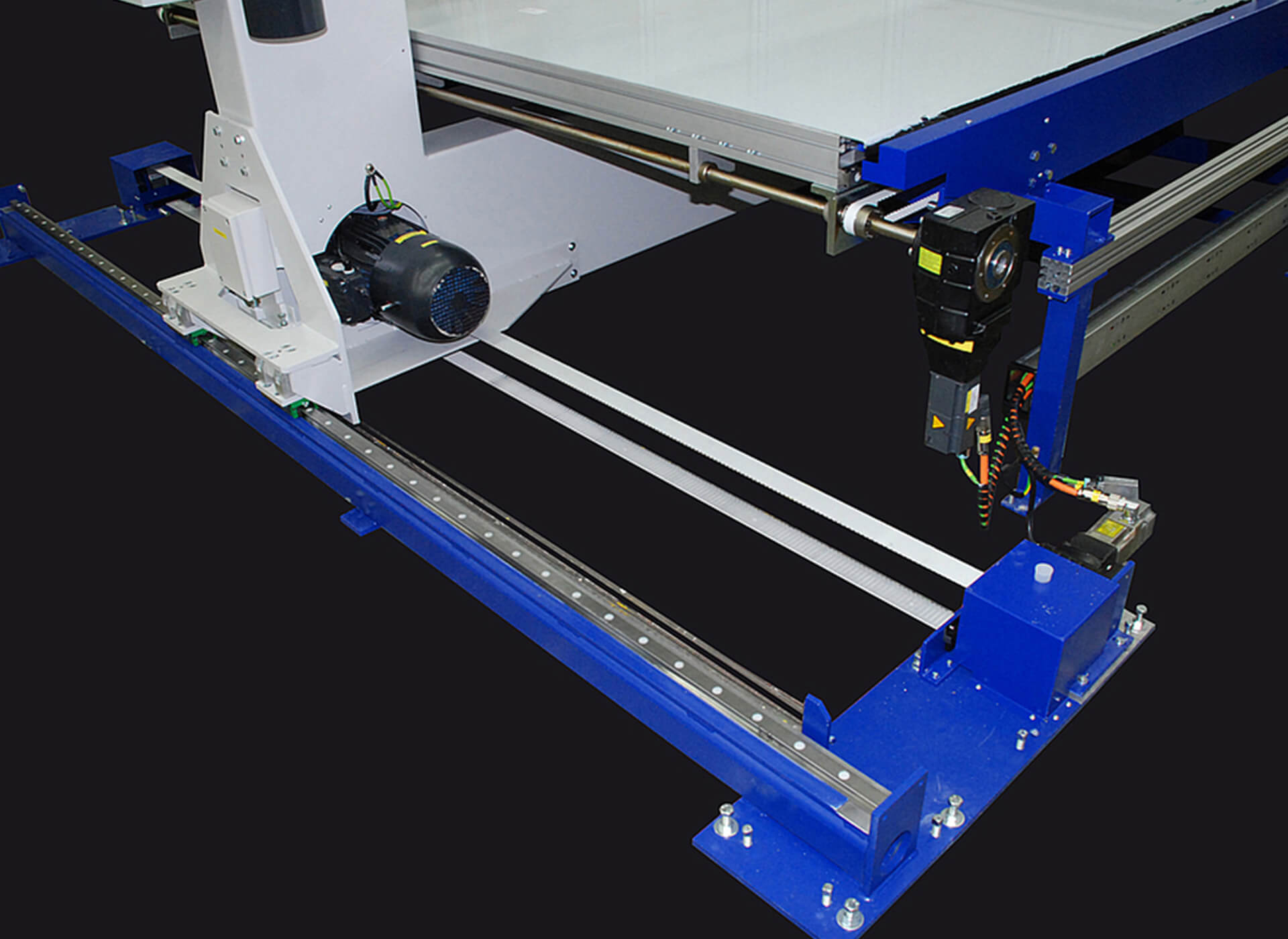

Vertical cutting machine to trim blocks and to cut sheets and rectangular cuts from sheets.

Technical data

Vertical cutting machine to trim blocks and to cut sheets and rectangular cuts. The IS-M with a movable cutting head and a stationary table cuts with very high cutting precision to reach the highest quality standards.

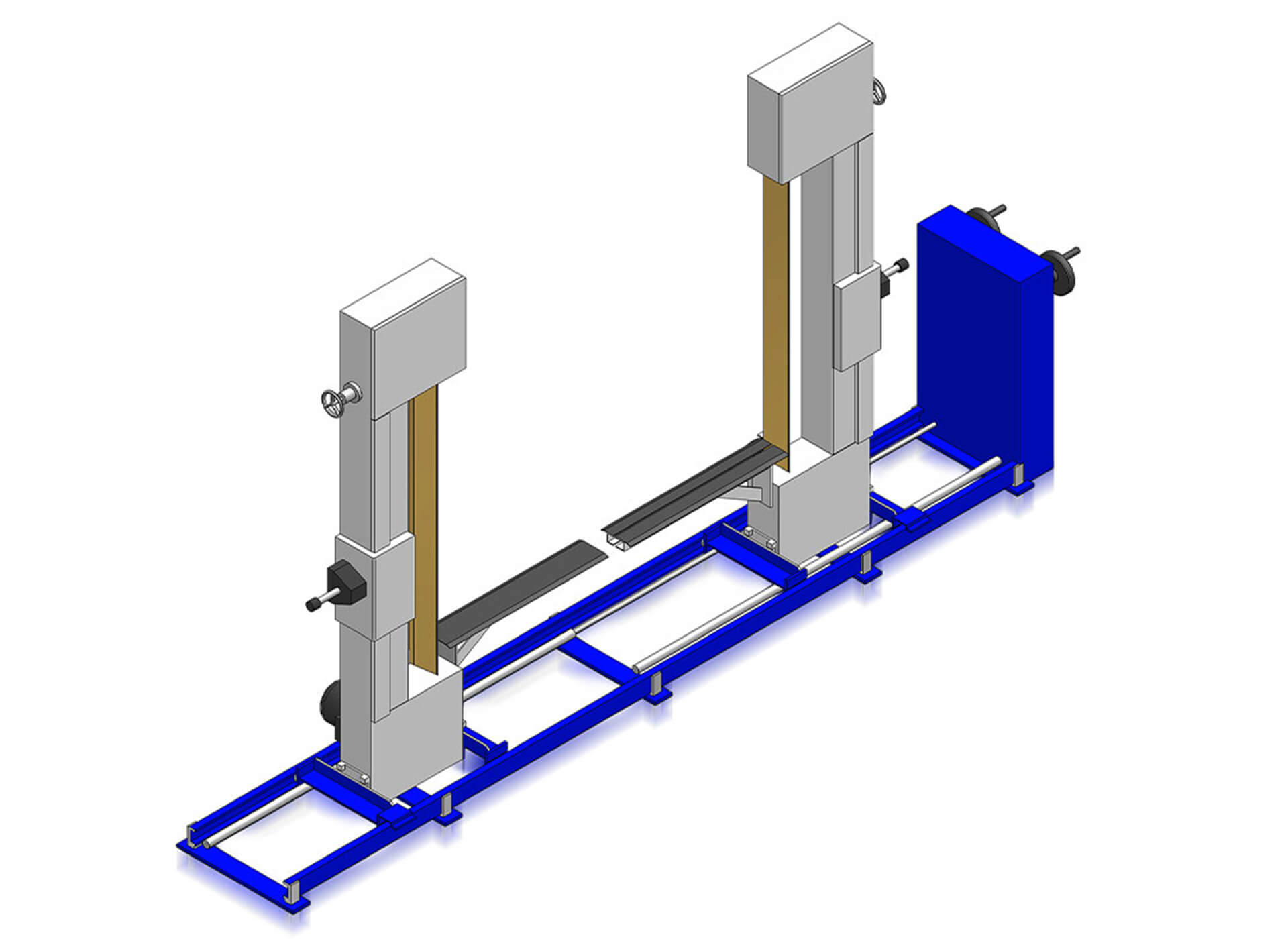

Dimensions

Standard Options Width 1.250 mm 1.600 mm, 2.200 mm, 2.500 mm Height 1300 mm 650 mm, 1.500 mm Length 2200 mm 2500 mm, 3100 mm Material

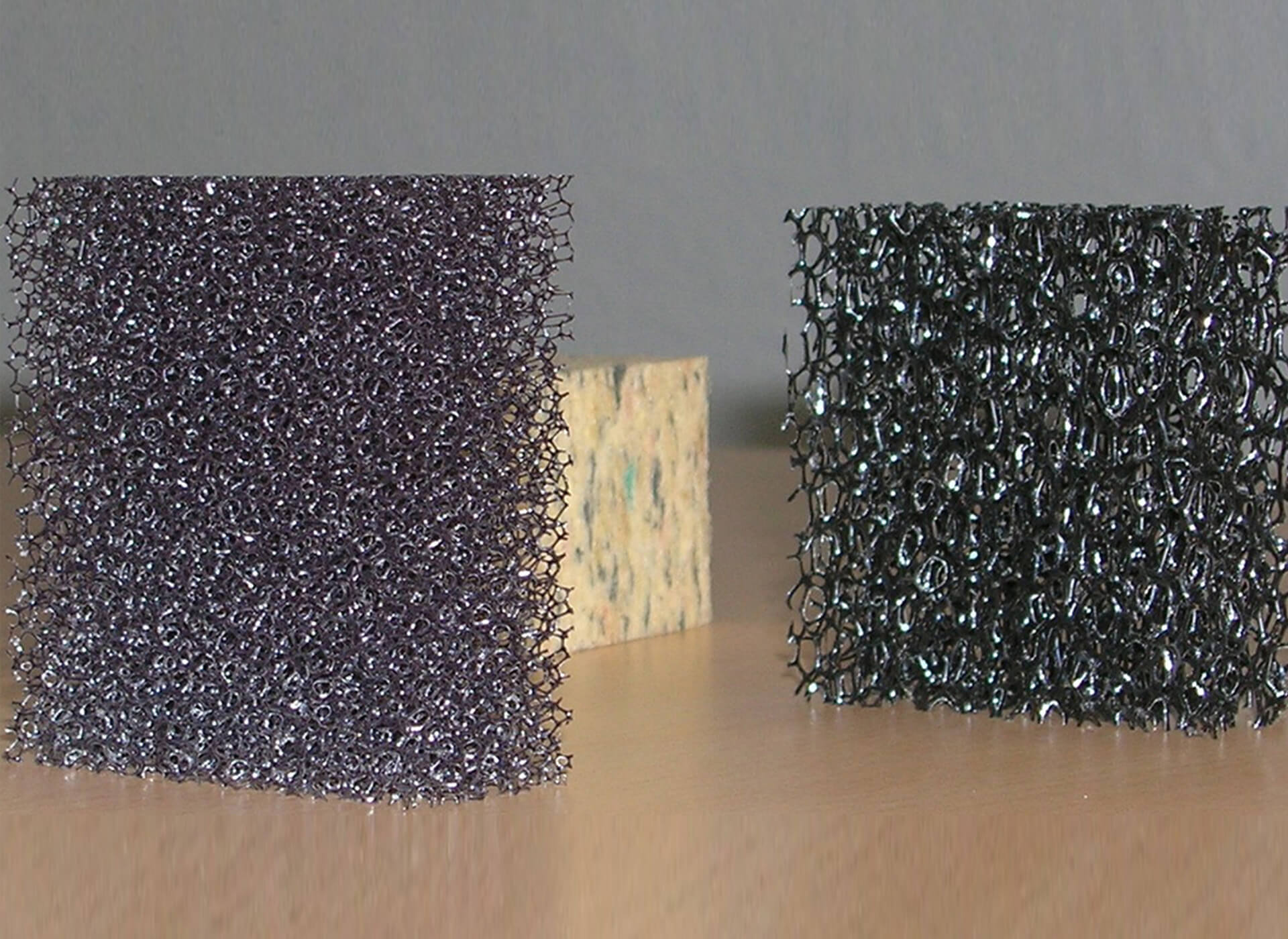

Ether-based polyurethane, flame-protected ether polyurethane, high resilience PU foam, viscoelastic ether-based polyurethane, flame-protected viscoelastic ether PU, combustion-modified highly resilient PU foam, reticulated ether-based polyurethane, ester-based polyurethane, reticulated ester-based PU foam, CM-PU ester foam, rebonded polyurethane, PU gel foam, extruded polyethylene, low density polyethylene, ethyl vinyl acetate (EVA), sponge rubber, natural rubber, mineral wool, viscose foam

Cutting tools

GBV4T, TB2 No. 11, TB2 42, TB2T-K18

Cutting speed

max. 40 m/min

Downloads

Standard

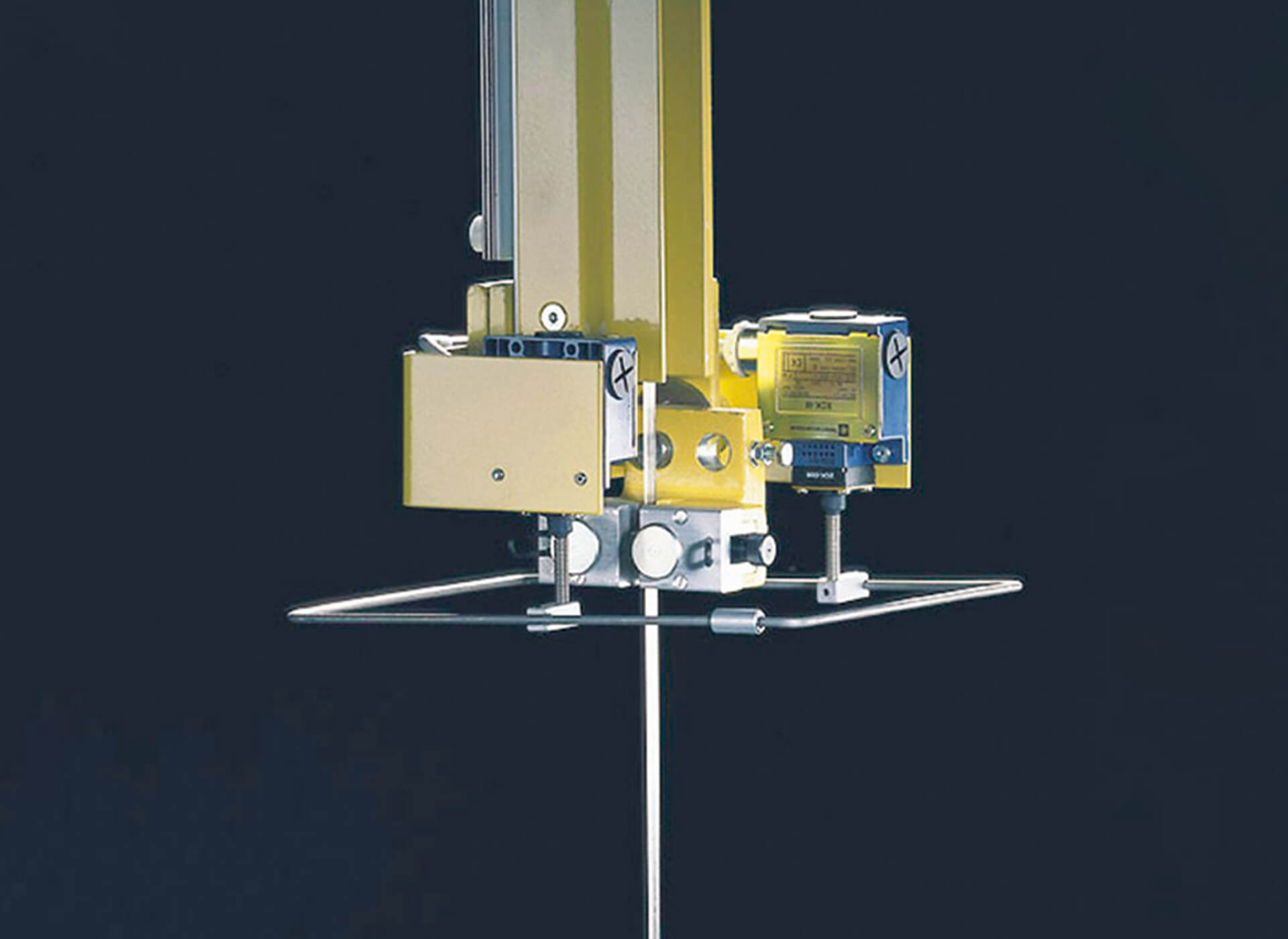

Motor-driven upper knife protection unit

Pneumatic knife tensioning support

Working table with an anodized aluminum surface

Right side stop

Options

Air cushion system

The air cushion system facilitates the handling of heavier blocks.

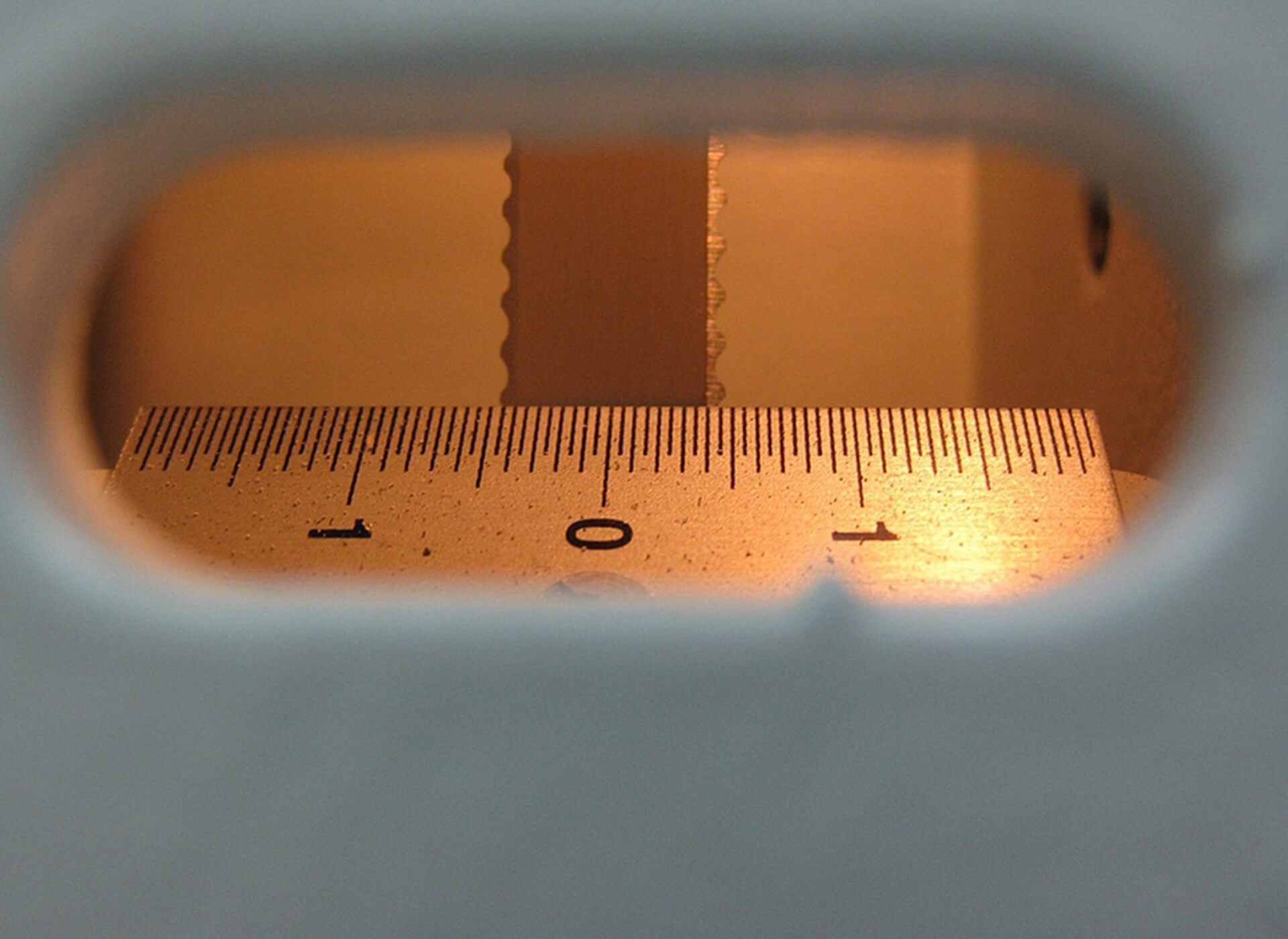

Optical knife-grinding control

Holding-down device

The holding-down device facilitates the fixation of the block so there is less movement of the material.

Band saw

The set knife is used for cutting harder materials.

Left working table as a turntable

for flexible working and processing of the whole block.

Continuously adjustable knife speed

The knife speed can be adapted to the material in order to obtain an optimal cutting result.

Left side stop increased from 750 mm to 1000 mm

Motorized upper knife guide

to come closer to the block and secure a precise cutting result.

Grinding unit

Efficient grinding with a very stable and powerful motor-driven grinding unit.

Grinding dust extraction

For extracting the grinding dust during the grinding process.